-

What are the uses of Jiangmen engineering plastics

2020-09-14 1598

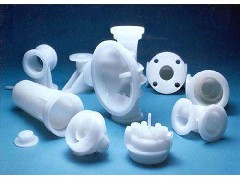

Jiangmen engineering plastics refer to industrial plastics used for industrial parts or shell materials. They are plastics with excellent strength, impact resistance, heat resistance, hardness and aging resistance. Engineering plastics refer to the plastics that do structural data in engineering. These plastics generally have high mechanical strength, or have outstanding functions such as high temperature resistance, corrosion resistance and wear resistance, so they can replace metal to do some

-

Is Jiangmen engineering plastics affected by temperature

2020-09-14 1505

In recent years, more and more attention has been paid to the influence of humidity on polymer materials. One of the scenes is the influence of humidity on the reliability of equipment in the field of microelectronics and MEMS, such as swelling and deformation of materials, cracking and stress concentration; The second is the aging problem of polymer materials in engineering application. Aging will reduce the function of polymer materials. The influence of humidity on engineering plastics is con

-

Why does Jiangmen engineering plastics warp and deform

2020-09-14 1546

Warpage is one of the common defects in injection molding of thin shell plastic parts. Due to the conjecture of warpage deformation, the warpage rules of injection molded parts with different materials and shapes are quite different. When the warpage exceeds the allowable error, it becomes a forming defect, and then affects the product assembly. It is a useful condition for controlling warpage defects to guess the warpage deformation of a large number of thin-walled parts (wall thickness less th

-

What are the applications of Jiangmen engineering plastics

2020-09-14 1533

Engineering plastics are thermoplastic plastics that can be used as structural materials. Engineering plastics have inductive functions, such as high rigidity, small creep, high mechanical strength, good heat resistance and good electrical insulation, which can be used in harsh chemical and physical environment for a long time. Advantages of engineering plastics engineering plastics have the advantages of low density, light weight, high specific strength, good insulation, scale stability and cor

-

What is the melting temperature of Jiangmen engineering plastics

2020-09-14 1594

Although the differentiation temperature of modified ABS plastics is as high as 270 ℃, due to the influence of other process conditions, the resin often starts to change color at about 250 ℃. If the temperature is below 20 ℃ but light color and high gloss products are made, if it is necessary to shut down for 15 minutes or more, the barrel temperature should be reduced to 120 ℃. In order to prevent the differentiation of flame retardant during the start-up or shutdown process of modified fire-re